Crane safety incident causation model

For the PDF version click here.

Purpose of this guide

Cranes are a critical feature of construction operations. They are also assessed as being one of the most dangerous items of equipment on a construction site. In Australia, 47 workers were killed in incidents involving cranes between 2003 and 20151. Safe Work Australia also reports that there are, on average, around 240 serious injury claims arising from crane safety incidents every year2.

This guide identifies causes and contributing factors associated with safety incidents involving cranes in the construction industry. It is based on research evidence and feedback received from industry experts and informed workers.

Background

Research was commissioned by the NSW Centre for Work Health and Safety to identify the factors that contribute to safety incidents involving cranes in the construction industry.

Industry experts participated in interviews and focus groups to capture a range of views about how and why safety incidents involving cranes occur. Construction companies, crane operators, training providers, regulators and other industry experts participated in the data collection.

The data was systematically analysed to identify factors contributing to crane safety incidents in the construction industry.

A crane safety incident causation model was developed.

This model collates factors identified by participants as causes/contributing factors to crane safety incidents in the Australian construction industry. The validation of the causation model showed that the findings were relevant to both mobile and tower crane incidents.

This guide:

- presents the crane safety incident causation model, and

- suggests ways that the model can be used by industry to understand and prevent crane safety incidents.

Key findings

The crane safety incident causation model organises contributing factors according to their proximity to or distance from the incident. It was based on a model of construction safety incident causation developed in the UK3.

The original model was generic and did not reflect factors contributing to a particular class of safety incidents.

The use of this model to understand the factors contributing to safety incidents involving cranes is therefore a new development.

The crane safety incident causation model

The research identified factors contributing to crane safety incidents at multiple levels within the work systems of the Australian construction industry.

Work systems vary include workers, tasks, tools, technologies, the physical work environment and the organisation of work. These elements interact with the physical and psychological health and safety of workers.

The results reveal that the factors causing or contributing to crane safety incidents operate at different levels of the construction industry’s work system.

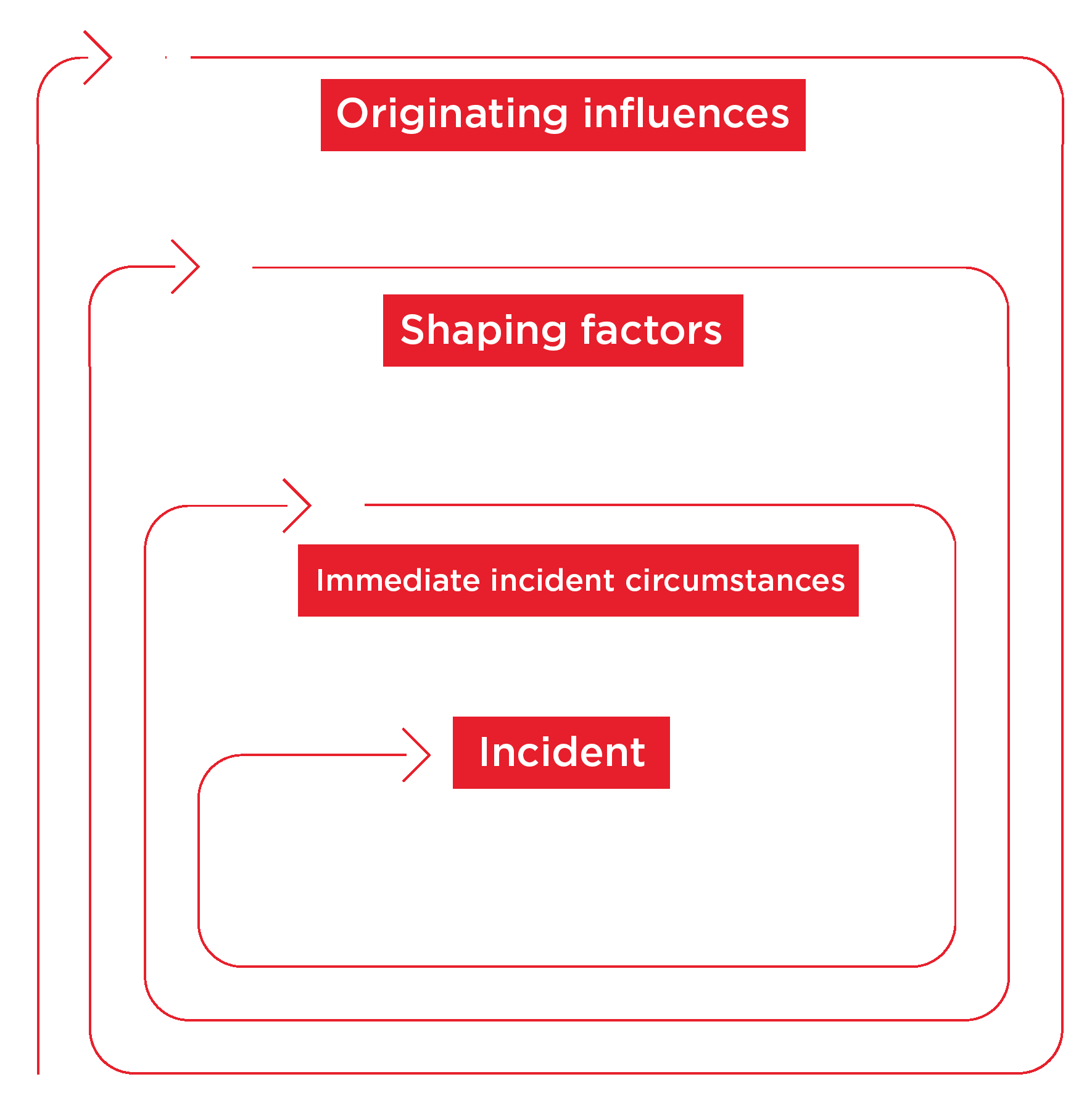

Factors contributing to crane safety incidents were classified as:

- originating influences

- shaping factors, or

- immediate incident circumstances.

These factors are shown in Figure 1, the crane safety incident causation model.

The outer layer of the model shows originating influences operating within the regulatory, economic and social environment within which the construction industry operates.

The middle layer of the model shows shaping factors, including those related to workers, job requirements and the management of crane activities at a worksite.

The inner layer of the model shows immediate circumstances related to workers, materials/equipment and aspects of the physical site environment.

It is important to note that these factors do not occur in isolation and their effects are likely to be interrelated – both between and within layers of the model.

How to use the model

The crane safety incident causation model can be used as:

- a tool to support investigation into the factors contributing to crane safety incidents in the construction industry, or

- a tool to identify risk factors, and to proactively plan for safe crane operations in construction worksites.

Originating Influences

Commercial factors

- Client demands

- Overheated procurement environment

- Procurement methodology selected

- Principal contractor’s expectations

- Time/budget pressures

Industry context factors

- Adjoining property owners’/community expectations

- Ageing crane fleet

Labour-related factors

- Crane contractor’s experience

- Different safety structures in EBA/Non-EBA worksites

- Increase in NTI (new to industry) and migrant workers

- Shortage of skilled workers

Project risk management factors

- Lack of early involvement of the crane contractor

- Peer review of approach/certification

- Poor communication and planning

- Principal contractor’s safety management practice/capability

- Unrealistic project timelines

Regulatory factors

- Authority/regulator’s permit conditions

- Disconnect between industry standards and regulatory requirements

- Inadequate regulatory training requirements

- Lack of consistency in training standards

- No crane registration completed

- Overseas import/substandard equipment

- Training not meeting the needs of the industry

Shaping factors

Crane service procurement factors

- Overcommitted crane company

- Risk factors associated with dry vs wet hire

Site management factors

- Change of plan/circumstances

- Documentation too generic/not site specific/poorly written

- Inadequate/incorrect information provided to crane company/operator

- Inadequate site supervision

- Lack of co-ordination and planning across multiple sub-contractors

- Lack of standardised processes

- Not recognising/accounting for changing site conditions

- Owner Procedure doesn’t address/cover high risk activities

- Proximity to existing structures on site and adjoining properties

- Requirement to submit Safe Work Method Statement (SWMS) prior to job commencing

- Safety documentation too long/complicated to read

- Sequencing of activities not appropriate

- Site constraints

- SWMS done in isolation (does not consider other site activities)

- ‘Tick and flick’ approach to documentation

Job factors

- Fatigue

- Long working hours

- Shift work/roster schedule

- Unrealistic workload/work pace

- Working outside of standard working hours

Plant management factors

- Lack of maintenance of plant

- Lack of/poor safety in design

- Modifications made to the crane

- No specific requirements for cranes and their design for safe operations

- Poorly written/generic/poorly translated manufacturer’s manuals

Worker factors

- Complacency/over confidence

- Inadequate on-boarding/induction of NTI and migrant workers

- Inexperience or insufficient skill of operator/dogman/lifting coordinator

- Pressures on crane operators to ‘get the job done’

- Stress/mental ill-health

- Transient workforce

Immediate incident circumstances

Material/equipment factors

- Crane too small for tasks being performed

- Loads being carried too heavy

- Load transfer too far

- No lift plan/plan not reflective of situation

- Operating substandard crane

- Structural/electrical failure of crane

Site factors

- Changes to ground conditions

- Crane located above/below ground services

- Existing soil conditions

- Lighting/visibility

- Negative interaction between adjoining tasks/activities on site

- Supporting structure not adequate

- Working in unsuitable weather

Worker factors

- Hazards not identified

- Lack of hazard awareness

- Lapse of concentration

- Not following manufacturer’s instructions

- Not following procedures/SWMS

- Override safety technology

- Unfamiliar with plant being operated