WHS using BIM: Phase Three Report

Executive Summary

Construction presents high rates of fatalities and injuries and is known as one of the most dangerous industries in which to work. Many safety incidents, injuries and fatalities could be prevented through improved design, planning and communication. While its adoption has been varied and inconsistent, Building Information Modelling (BIM) is an enabling technology that can play a significant role in improving work health and safety (WHS) in this sector. Indeed, BIM offers an opportunity to support the elimination or mitigation of WHS risks through improved data and information management and communication; specifically, by enabling the generation and management of digital design and construction information from which WHS hazards and related risks can be better identified and managed. Data as an asset to manage is core to this suite of guidelines in the BIM for WHS Management Decision Framework.

There has been a plethora of research studies in the past decade that have analysed the adoption of BIM within the industry in an attempt to improve communication, information flow, efficiencies and productivity. Equally, there has been numerous studies that have explored maturity and capability for adoption, identifying the need for new competencies and new models for adoption. The present study went a step further and leveraged innovative international practices that apply BIM specifically to work health and safety to deliver the BIM for WHS Management Decision Framework. The framework has four key components and provides guidelines to assist clients and their leadership teams on projects in developing the information environment that can support the integration of BIM for WHS management. Both public and private sector clients have much to gain from improved safety records.

One major challenge of the construction industry is to find ways to reduce WHS incidents and injuries to support a safe workplace. The use of BIM can facilitate the early identification of potential WHS issues and the application of preventative strategies using automated approaches. The strengths of using BIM for WHS management manifest in the embedded processes of visualisation, simulation, analytics, evaluation, and monitoring. It also supports communication, education and training during the design, construction, operational phases and post-construction phases. Documenting WHS requirements in plans and monitoring compliance with WHS legislation within a BIM-environment can result in safer working conditions as WHS is identified as an integral part of the construction process, is made more visible to stakeholders, and can be appropriately managed at the various stages of construction.

Australia lacks research that evaluates WHS management in a BIM-environment. BIM-enabled WHS management is rarely considered in construction tender requirements and the evaluation of bidders’ proposals, despite the scope for BIM to provide a powerful approach to the management of WHS. The management of WHS is likely to be most effective when considered holistically as part of the project lifecycle and included in a BIM-enabled environment by the construction procurer, with commensurate client response at the construction tender and evaluation stage. This allows WHS requirements to be embedded early in the design and construction process and facilitates increased clarity for the management of WHS across the project lifecycle. The UK, Singapore, Hong Kong and Finland public and private sectors are further advanced in the adoption of BIM and its use for WHS management. They provided valuable research sites that could enrich information on the approaches, tools and outcomes highlighted by the theoretical, prototype and evaluative studies in this area. Sufficient examples of Australian private and public sector BIM-enabled construction projects now exist to allow evaluation of BIM, from the tendering stage through to post-construction, and the potential creation of management and information systems for monitoring WHS. There also appears to be sufficient experience among industry and government stakeholders for major infrastructure projects to develop models for the adoption of BIM-enabled WHS management systems. Clearly, the brave new world of BIM holds potential for supporting the fulfilment of WHS obligations, and it is timely to harness the potential of BIM to ensure safer construction sites.

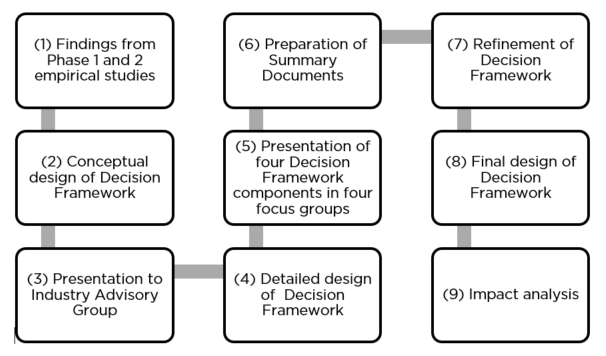

This Technical Report is the culmination of a study involving significant industry liaison and input. The study is part of a worldwide trend to develop better tools for collaborative decision making on construction projects through improved information ecosystems, including ‘guidelines’ to enable public and private sector client organisations who are key industry influencers to lead projects in a new way. The study explored the clients’ role in catalysing a BIM-enabled WHS management ecosystem by incorporating it in procurement strategies and tendering requirements. The resulting Decision Framework provides valuable insights for researchers and practitioners to understand how a BIM-enabled WHS management system can best be facilitated during the procurement process and supported throughout the entire project lifecycle. This Technical Report is focused on the third phase of the four-phase study. Phase 3 of the study consisted of a comprehensive nine-step methodology (see details in Figure 1) to include iterative feedback from industry to develop, refine and analyse the potential impact of the content of the Guidelines.

The purpose of the Decision Framework is to provide industry guidelines that seek to support the development of a digital data and information management ecosystem that synthesizes BIM and WHS management across the entire life cycle. The Decision Framework aims to move from the generic approach of BIM adoption to a targeted approach as BIM as an enabler of achievement of a project objective (i.e., safety) with specific exemplars, case studies and tools orientated towards that objective. The Decision Framework provides guidance on how to develop an Organisation Information Requirements document that supports the Project Information Requirements document, particularly in enabling the development of high-quality criteria for tendering, evaluation and monitoring, and ultimately, the delivery performance of the primary contract throughout the supply chain. To develop the Decision Framework, case studies, document analysis and semi-structured interviews were conducted. BIM and WHS management toolkits and resources were also examined (UK BIM Framework 2020a, 2020b), including those provided by the UK-based BIM4WHS Working Group (UK BIM Alliance 2020); and guidelines and standards such as the NSW Infrastructure Development Management Framework (NSW Government 2020) and ISO 19650 (International Organization for Standardization 2018; 2020) have also provided a much-needed context to this potentially challenging task of bringing two worlds together of “BIM” and “WHS”. The following diagram summarises the nine-step process undertaken in Phase 2 (Steps 1-3) and Phase 3 (Step 4 onwards).

Figure 1: Phase 3 Method

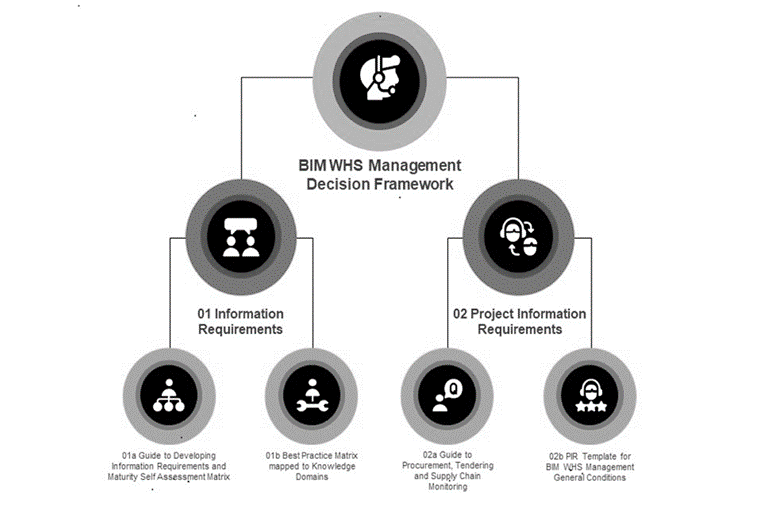

Figure 1 indicates that the BIM for WHS Management Decision Framework was built from the synthesis of the outcomes of Phase 1, i.e., desktop literature review and preliminary interviews with experts, and Phase 2, an in-depth empirical study which resulted in the recommendation of guidelines with four components, the purpose of each component and the principles for development in Phase 3. Figure 2 summarises the key purpose of each component.

Figure 2: BIM for WHS Management Decision Framework principles

The BIM for WHS Management Decision Framework is structured in a hierarchy, as indicated in Figure 3. It is composed of two sets of guidelines: Information Requirements guidelines and Project Information Requirements guidelines.

Figure 3: Hierarchy of Decision Framework guidelines

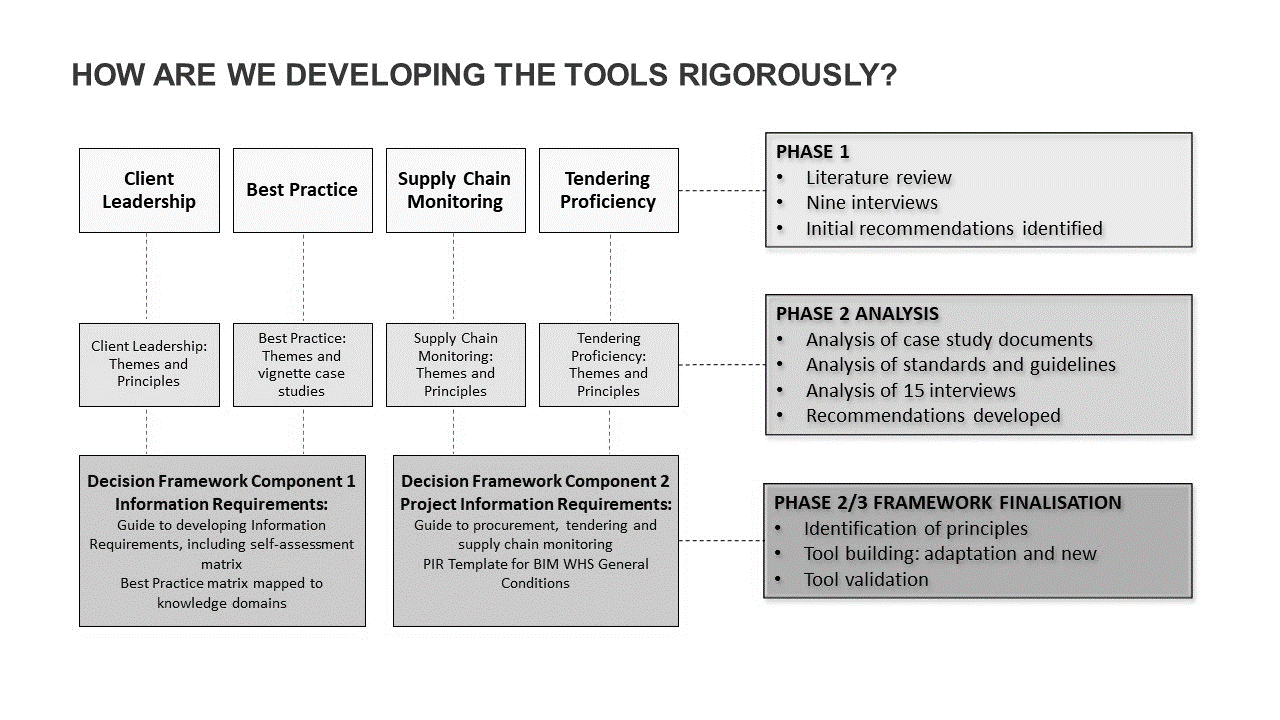

The Phase 2 interviews, analysis and themes provided significant input to the Decision Framework text for case studies and the various sections. As discussed in Phase 1 and Phase 2 Technical Reports (London, et al., 2020; London, et al., 2021), the proposed Decision Framework supports pathways for clients and project team leaders to collaboratively work together and develop high-quality information requirements that clarify the data management environment expectations for all stakeholders at an organisational, asset and project level. Figure 4 summarises the development, testing and validation of the guidelines throughout the study and the relationship between Phase 1, 2 and 3 activities and the research findings.

Figure 4: Integration Phase 1, 2 and 3 Key themes and Activities for Decision Framework development.

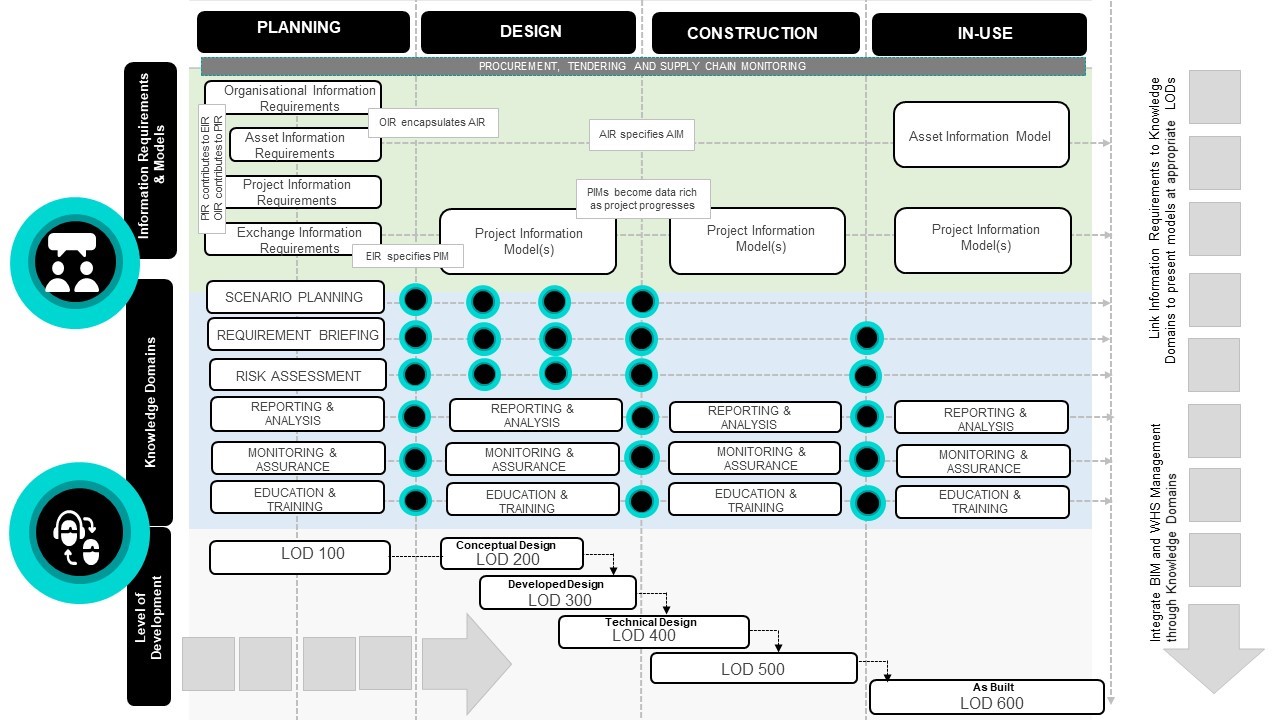

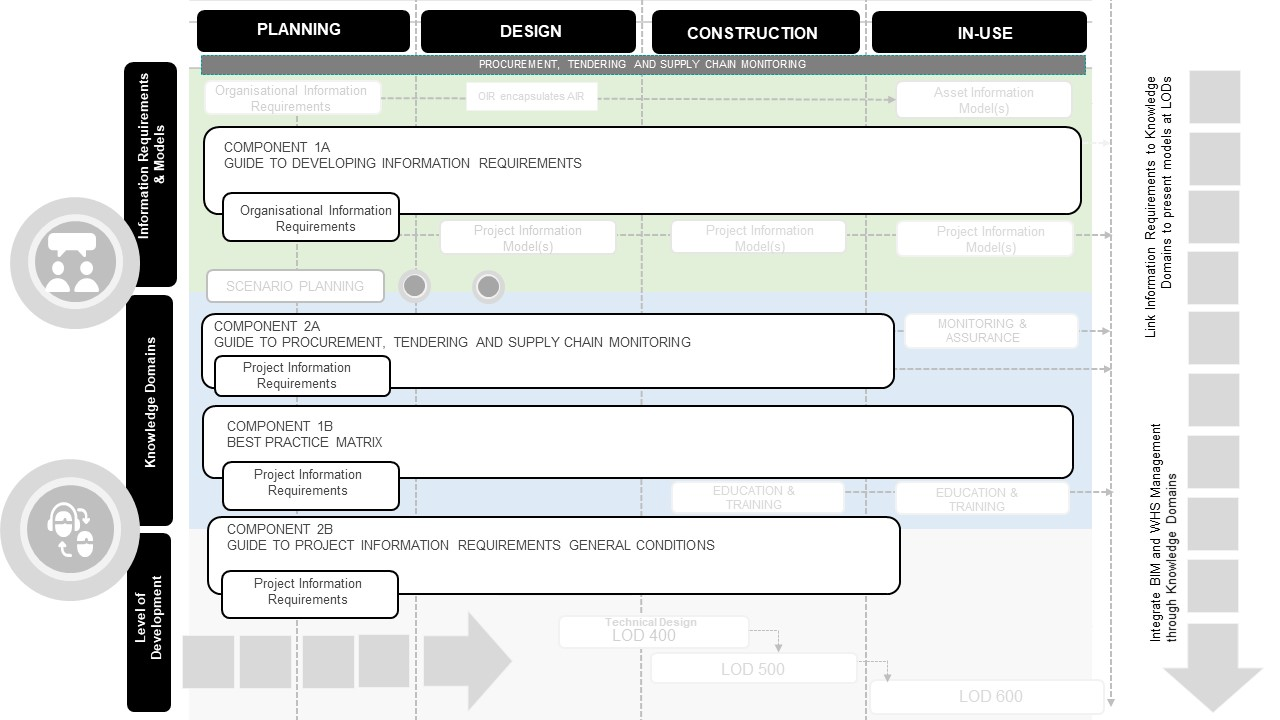

Components 1 and 2 are companion documents that include guidelines. The Information Requirements (Component 1) provides a strategic discussion for public and private sector clients to establish themselves as leaders in establishing the planning, designing, constructing and managing assets lifecycle in a safe manner. The Information Requirements align with the strategic approach as outlined in NSW Infrastructure Development Management Framework, and it also follows an international trend for integration of BIM (digital engineering/digital twinning) to improve project management and project performance. Concepts such as Organisational Information Requirements and Project Information Requirements are explained, and a practical case study of how to develop such documents is provided based on the international standards. A Self-Assessment Maturity Matrix is also introduced aimed at early adopters, leaders and innovators, specifically targeting BIM and WHS integration. Best practice case studies are also provided, drawing from both the international literature and empirical fieldwork conducted in NSW; specifically, four best practice case studies from Australia and ten international exemplars are presented that give practical examples to organisations of what is possible. The inter-relationships between a project lifecycle, the information requirements and models, the knowledge domains and the level of development of a model are explained to give guidance to the Decision Framework users. The following diagram (Figure 5) is unique and was developed specifically for these guidelines.

Figure 5: Inter-relationship Project Lifecycle, BIM Level Development, Knowledge Domains Information Requirements and Models

The Project Information Requirements Guidelines (Component 2) provide strategic guidance for public and private sector clients to build capability throughout their own organisations and throughout the supply chain at the project level. The first guide explores procurement strategies, tendering and supply chain monitoring, with a particular emphasis on creating the environment for the project leadership team to develop authentic tender criteria and evaluate tenders appropriately. The second component focusses on a particular example and presents principles for ‘lifting’ in the construction industry, one of the most dangerous aspects on a site. The following diagram summarises key concepts explained in relation to developing information requirements and their inter relationships; for example, between the asset life cycle, the OIR (Organisational Information Requirements), AIR (Asset Information Requirements), PIR (Project Information Requirements) and EIR (Exchange Information Requirements) and the Level of Development and the Knowledge Domains.

The following diagram (Figure 6) summarises the relationship between the various guidelines and the LOD, Knowledge Domains and OIR, EIR, PIR and AIR and can be found in the guidelines. Each of the four guidelines can be read independently.

Figure 6: Guidelines mapped to project lifecycle

Two case studies involving an assessment of the potential impact of the Decision Framework were conducted based upon available project documents. For Case Study 1, the conclusion was that the Decision Framework had at least three potential benefits and would have potentially impacted numerous positive outcomes:

- If the Decision Framework was used, a strong and novel emphasis would have been placed on BIM/WHS management integration. High-level Organisational Information Requirement documents indicated an emphasis on safety but not on BIM. In contrast, the Project Information Requirements and Exchange Information Requirements indicated significant support for the use of digital data, but this emphasis was not explicitly linked to safety goals. Multiple references were made to using digital data to improve construction processes, specifically in terms of improved constructability and more efficient sequencing. However, how these would translate into better safety performance outcomes, for example, a reduced critical incident frequency rate, was not made explicit. This could be reflective of a common yet debatable stance in the industry: that safety is a by-product of better design and construction rather than a goal in itself. Another example is that project data schemas and project data building blocks were specified to support objectives related to time and cost savings, but not safety objectives.

- If the Decision Framework was used a broader suite of strategic goals, including identifying, recruiting, developing and monitoring supply chain partners, redesigning tendering criteria to capture work health and safety goals and creating environments where even subcontractors could catalyse BIM for WHS innovations, would have been taken into consideration in a much more explicit manner.

- If the Decision Framework was used, the use of digital models would have been mandated in systematically identified domains from the outset of the project. The use of 4D as a starting point would have been emphasised. Instead, information requirements that were analysed were found to frame model use as “nice to have” even in critical activities, with specifications saying that “4D models (3D models + time) may be used” or that “3D models can be used for safety planning”.

For Case Study 2, at least six benefits were identified as potential decision framework contributions:

- As in Case Study 1, strategic goals integrating Digital Engineering/ BIM and WHS management would have been captured in high-level organisational information requirements instead of being confined to project objectives. The proposed Decision Framework recommends foregrounding “integrated” BIM/ DE for WHS management consistently across all tiers of goal: project-specific goals as well as in organisational objectives that transcend project goals. The Decision Framework would sensitise users to the fact that, in this case, BIM/WHS integration is emerging at the project level but remains inconsistent at the higher-level vision documents and in organisational-level targets.

- If the Decision Framework had been used, supply chain capability requirements for the project would have been clearly defined before project planning. Case Study 2 project documents offer general statements stating that the supply chain is expected to have the “ability to use models for a range of purposes”. Documents do not specify required knowledge, skills and competencies, a practice recommended in the Decision Framework. Follow up interviews confirm this as an area for improvement.

- Tender evaluation panels would have been broadened to include professionals with expertise in BIM-enabled WHS management. In Case Study 2, there is no clear evidence that WHS management professionals or someone with knowledge and experience in identifying WHS risks, participated in tender evaluation, although findings do suggest they were involved early and regularly in the project. The Decision Framework recommends that tender evaluation panels should be diversified to include professionals capable of assessing a supply chain’s WHS methods, capabilities and performance.

- Assessment of tender submissions, including the pre-contract DEXP, would have been conducted in a much more rigorous manner. In the case study, assessment of this submission has been described as being something of “a light touch”. Documentary evidence indicates that the client-defined certain content to be included in the pre-contract DEXP: explanations about the structured sharing and use of digital data, strategies for model sharing, approaches for clash detection. Follow up interviews indicate that assessment was not particularly rigorous, with some aspects of the tender evaluation being described as “subjective” and limited to binary decision-making, for example, checking “whether an item was (simply) mentioned or not”. The Decision Framework proposes strategies to counter this.

- If the Decision Framework had been utilised, more comprehensive strategies for managing digital data related to safety would have been implemented. In Case Study 2, “Safety” was a metadata identifier allowing the tagging and collection of safety data, which is clearly a useful development. However, such digital data management was still sub optimised as much of it was compiled into spreadsheets instead of being incorporated into the model. The Decision Framework highlights the need for establishing the currency and accuracy of WHS data, and while there is emerging evidence of the ability to build a repository of WHS information through the management of digital safety data, the full potential of digitally-supported WHS decision-making has not yet been attained.

The suite of guidelines is the beginning of a new approach to improving the adoption of the integration of BIM for WHS management in our industry. The next step is to develop more detailed guidelines and standards at the project level to support the strategic approach presented in this study. It is time we did better. The final Phase of this study is focussed on Engagement to present the findings and outcomes of the study to industry and government. This does not include an Implementation and Evaluation Phase; however, that would be a useful future direction.